| ADVANTAGES OF THE BATCHMIX PLANT | ADVANTAGES OF THE DRUMMIX PLANT |

|---|---|

|

|

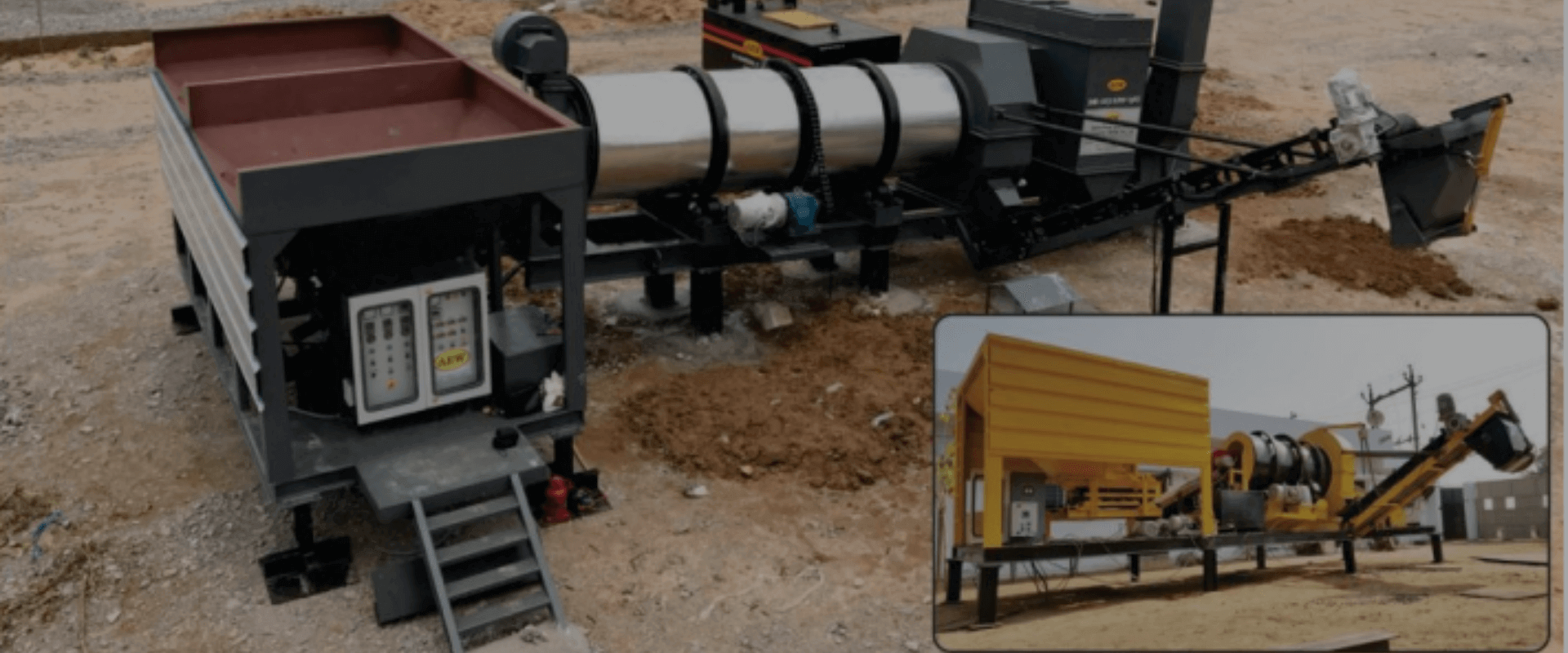

Asphalt Batchmix Plant & Drum-Mix Plant The major difference between Batchmix Plant and Drummix Plant is that in the case of Batchmix plant the resultant asphalt mixture is produced in batches which are usually of 40 to 50 seconds while in the case of Drummix plants,they are regarded as continuous mixing plants and the resultant mixture is produced continuously and without any interruption. Batchmix plant provides efficient gradation control of the raw material as compared to Drummix plant, so they are used as per the circumstances of the availability and the optimum graded quality of the raw materials.